Chemical industry – tested components for maximum process reliability

In the chemical industry, plant components must not only withstand extreme loads, but also function with absolute reliability. Henkel Rohrverformungstechnik supplies ready-to-install pipe systems and special assemblies for processes where quality, safety and precision are essential.

In addition, we supply collectors, distributors, external piping, as well as repair and replacement parts for large chemical plants. Our high level of vertical integration, variety of materials and many years of experience make us a reliable partner.

Typical applications of our complete systems:

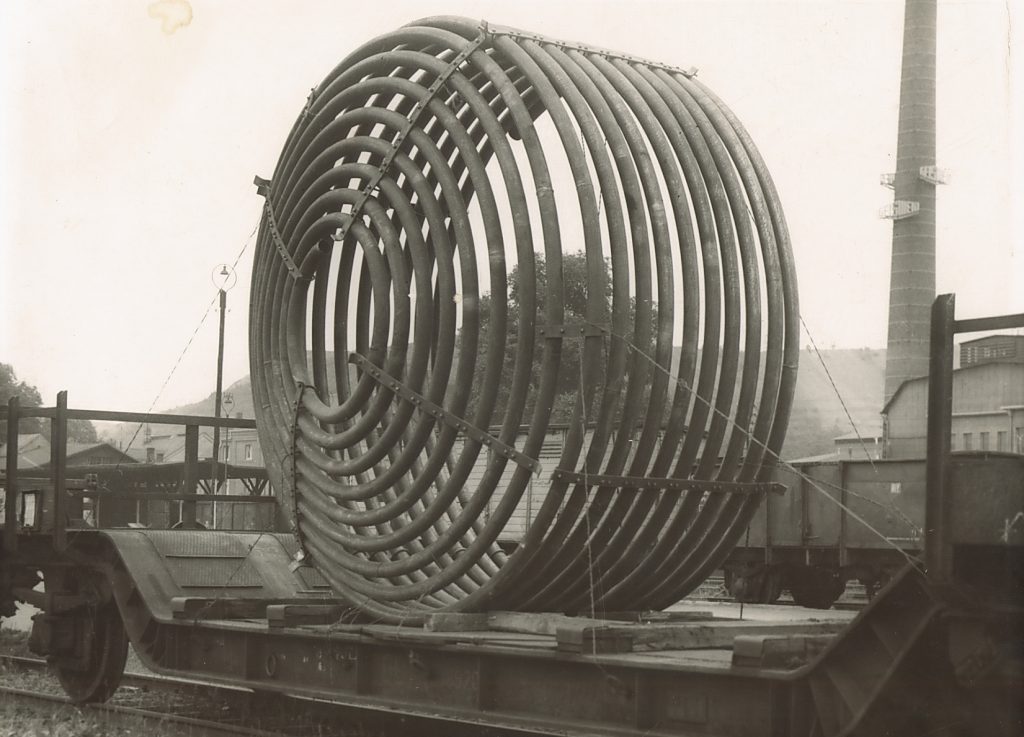

- Spiral planes and spiral bundles (single or multiple threads)

- Collectors, distributors and external piping

- ready-to-install complete systems

- Customised repair and replacement parts

Your advantages with Henkel:

- Proven quality for safety-critical processes

- Processing of demanding materials (e.g. high-alloy steels, nickel-based alloys)

- Complete inspection and documentation

- Ready-to-install delivery according to customer specifications

- Ready-to-install delivery according to customer specifications

Petrochemicals – reliable system components for extreme conditions

The processes in the petrochemical industry place the highest demands on materials, processing and product quality. This is precisely where Henkel Pipe Forming Technology delivers tailor-made solutions.

We manufacture ready-to-install synthesis gas coolers in various designs, general gas coolers and piping elements made from heat- and media-resistant special materials. Thanks to our many years of experience in processing high-alloy steels and nickel-based alloys, we guarantee durable and resilient components – precisely according to customer specifications.

Typical applications in petrochemicals:

- synthetic gas cooler

- Gas coolers for high-temperature processes

- Pressurised pipes and connecting elements made of special materials

- Welded assemblies for thermally demanding systems

Your advantages with Henkel:

- Precisely manufactured components for maximum thermal and chemical stress

- Processing of demanding materials such as nickel-based alloys, ferritic and austenitic steels, etc.

- Ready-to-install delivery with documented testing

- Experienced manufacturing team and modern plant technology

- Reliable partner for critical applications

➡ Rely on proven quality and reliable manufacturing for your petrochemical plants.

Pharmaceutical industry – pipe systems for the highest quality requirements

The pharmaceutical industry has extremely strict requirements in terms of hygiene, material purity and processing quality. Even the smallest deviations in tolerance or surface defects can jeopardise process reliability. Henkel Rohrverformungstechnik supplies tested coil tubes and components made from high-quality special materials – manufactured with precision for use in sensitive areas of plants.

We manufacture complete coil systems and individual elements with ground or polished surfaces on request – suitable for hygiene-critical processes and in accordance with industry-specific standards/regulations. Our clean workmanship, high vertical range of manufacture and experience with stainless steel materials guarantee the best possible product quality.

Typical applications in the pharmaceutical industry:

- Coils for temperature control in reactors or process modules

- Heat exchanger components for clean room environments

- Polished pipe systems for hygienically sensitive media transport

- Special components according to customer specifications

Apparatus and plant engineering – high-performance components for industrial process heat

The highest standards of dimensional accuracy, material selection and processing quality are required in apparatus and plant engineering. Henkel Rohrverformungstechnik supplies precision-manufactured heat transfer systems, thermal oil heaters and coil systems for use in process heating systems.

Our heat transfer systems/thermal oil heaters and coil heaters are manufactured with single or multiple passes and from a variety of materials. They are delivered as ready-to-install assemblies with lengths of up to 14 m and diameters of up to 4500 mm.

Whether it’s a one-off production based on drawings or repeatable series production, we supply precisely fitting components for the economical and safe operation of complex systems.

Typical applications in apparatus and plant engineering:

- Heat transfer systems, thermal oil heaters and coil systems

- Pipe components for heat exchangers and process modules

- Special assemblies for pressure and temperature processes

- Piping solutions in modular plant engineering

Your advantages with Henkel:

- Custom-made coil tubes up to 14 m in length and 4500 mm in diameter

- Processing of diverse materials – including for high-temperature applications

- Single or multi-stage designs according to specifications

- Experienced team and modern manufacturing technology